Intelligent Manufacturing

Murge has always been adhering to the customer first, market-oriented, quality-oriented business philosophy. The company has more than 90000 square meters of modern production plant, is committed to the implementation of lean production and intelligent manufacturing, the implementation of information technology and industrialization of the depth of integration, to create a digital factory. We have established a unique small-batch, multi-batch pull production model to meet the diverse needs of the market.

At the same time, we have introduced the excellent performance management model and passed a series of management system certifications, including quality, environment, energy, occupational health and safety, intellectual property rights and green factories. We have developed and implemented a full-process interconnection and collaboration platform, from market insight to delivery and settlement, forming three major control platforms based on data, business and technology, which are highly matched with our business scenarios and realize one-stop order management.

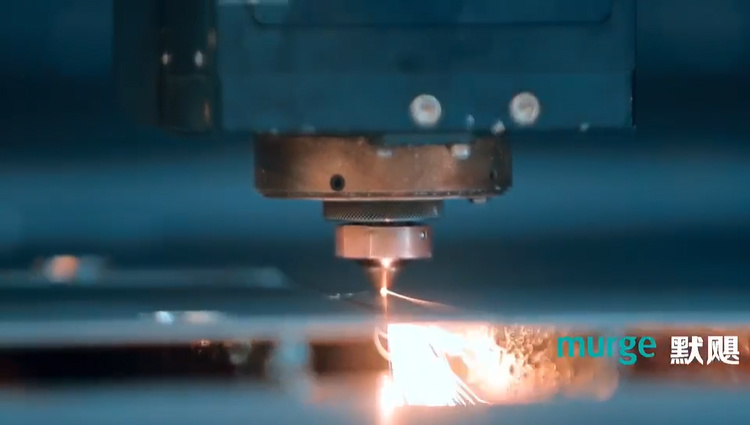

We have successfully built six flexible intelligent manufacturing workshops, including sheet metal, machine processing, pressure injection, injection molding, component assembly and complete assembly, and realized the deep integration of four core systems, including product life cycle management (PLM), enterprise resource planning (ERP), order management system (OMS) and manufacturing execution system (MES), it has promoted our rapid improvement in the four management directions of informatization, automation, lean and customization. Murge won the honorary titles of "Zhejiang Province production mode transformation demonstration enterprise", "Wenzhou digital workshop", "Wenzhou green low carbon factory", "Wenzhou intelligent technological transformation demonstration project" and "Wenzhou leading industrial enterprise.