Everyone talks about safety and everyone will respond to emergencies-a series of activities on the theme of "smooth passage of life"

Release time:

2024-07-08

June 2024 is the 23rd "safe production month" in the country. in order to implement the national security policy, strengthen employees' safety awareness of not occupying or blocking life channels, and enhance employees' ability to avoid emergencies, the silent hurricane division organized and carried out a series of safety production month activities such as knowledge training, actual combat drills and hidden danger investigation around the theme of "everyone talks about safety and individual meeting emergency-smooth life channels.

Create a safe production atmosphere

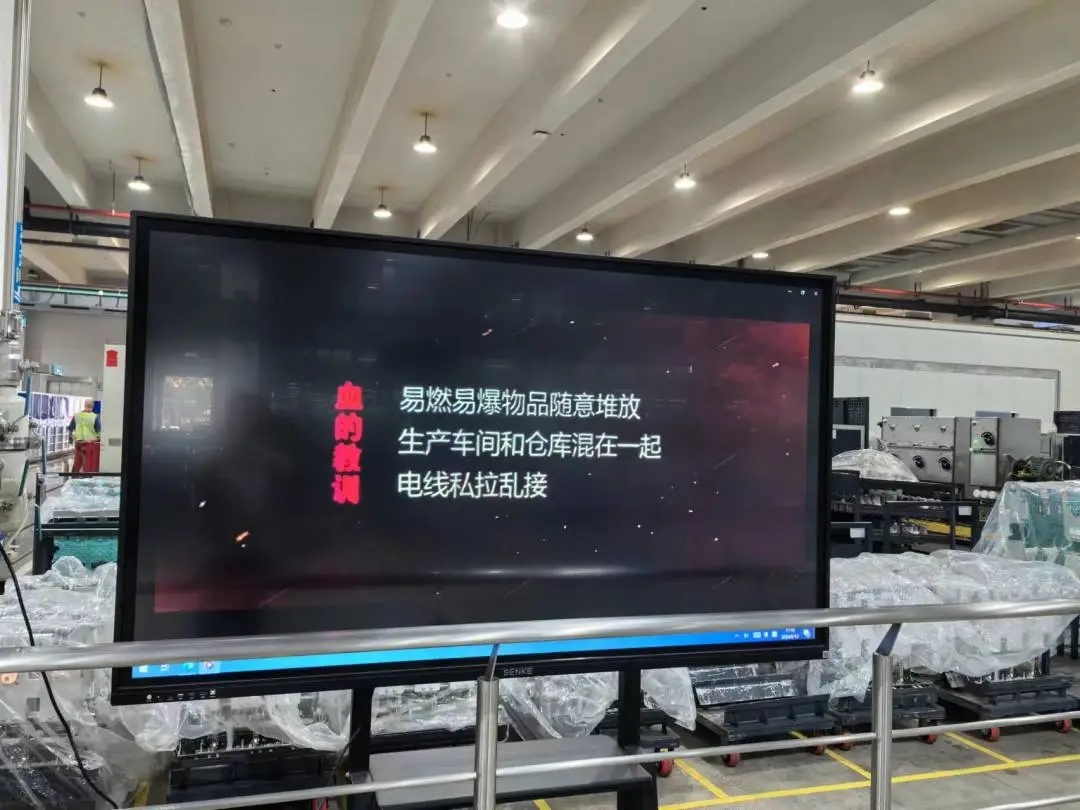

In the early stage of the activity, the coverage of safety publicity was comprehensively improved by issuing public tweets, rotating safety warning videos, posting safety knowledge posters, hanging safety banners and other forms, and the atmosphere of "everyone talks about safety, always wants safety, and needs safety everywhere" was actively created. The activity was slowly launched in a strong safety atmosphere.

Deepen safety education and training

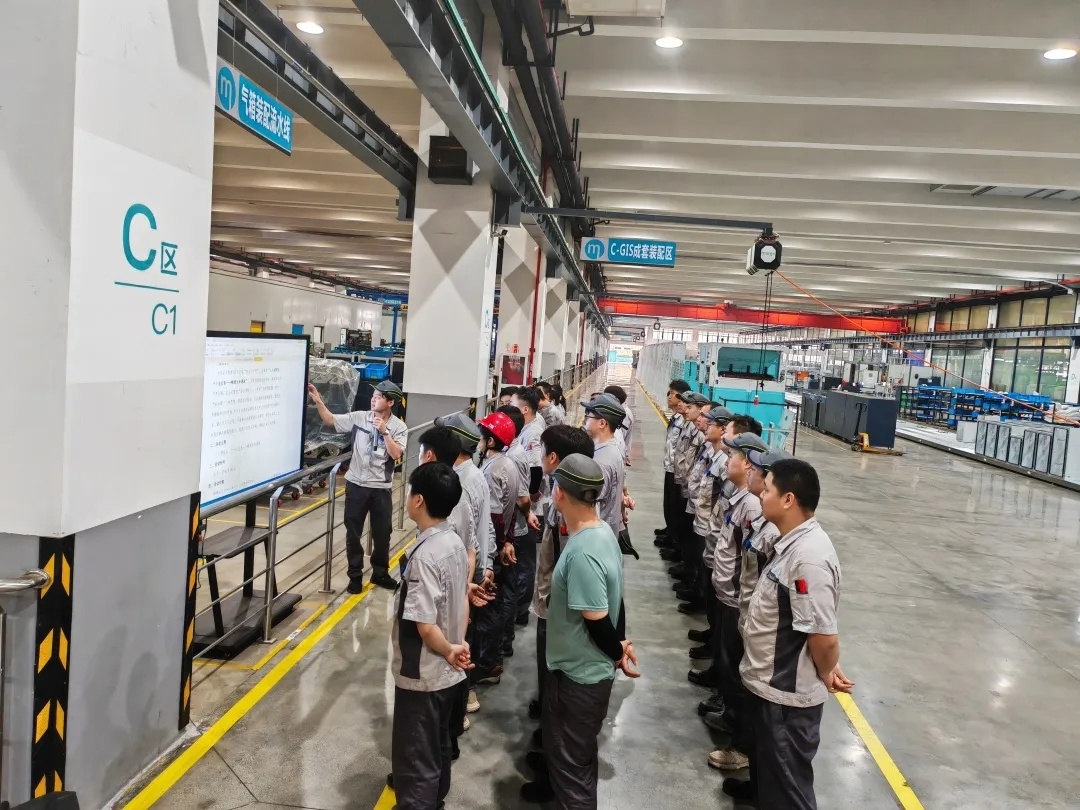

In order to implement safety education and popularize safety knowledge and skills, during the activity, safety training at all levels, such as company level, workshop level and team level, was carried out. The "unsinkable" Titanic and Murphy's law were used to lead to "the greatest danger is not aware of danger", and the alarm bell of "safe production is no small matter" was sounded in the hearts of all employees with vivid cases, use concise and clear steps to make employees memorize emergency rescue skills. The combination of theory and practice makes safety awareness and skills deeply rooted in the hearts of the people.

Carry out special safety investigation

A special inspection team is composed of electricians, mechanics, environmental safety engineers and other professionals to conduct a comprehensive investigation on the safety of the company's equipment, electrical, fire-fighting facilities, and tooling equipment protection facilities. In the process of investigation, each link and equipment were inspected in detail, and 77 problems such as damage to the pressure regulating valve of the manipulator and missing switch cover of the CNC punch were found on site. The inspectors recorded the problems in time and formulated detailed rectification measures to ensure that each hidden danger could be rectified in time and effectively.

Strengthen the actual combat strength of the drill

In order to standardize the emergency management and response procedures for safety accidents and implement emergency work in a timely and effective manner, the company has carried out warehouse fire emergency drills and life passage activities. In the process of accident discovery-emergency treatment-life passage, each group has a clear division of labor and responds to sudden accidents quickly and orderly. By simulating real events and emergency handling processes, all employees can truly understand emergencies intuitively, truly understand that fire exits cannot be blocked and how to use fire fighting equipment, and enhance their emergency rescue capabilities. ESSD summarized the emergency drill, clarified the necessity of the emergency drill, pointed out the problems found and needed to be improved during the drill, and proposed that we should be vigilant at all times and jointly create a safe working environment.

This safety production month activity highlights the key role of life channel in escape and emergency rescue, and improves the ability of employees to master accident emergency knowledge and skills. Safety work has only a starting point and no end. Next, the company will continue to carry out dormitory fire emergency drills, bus escape emergency drills and other activities, and strive to create a good safe production environment and escort the company's high-quality development.

Related News